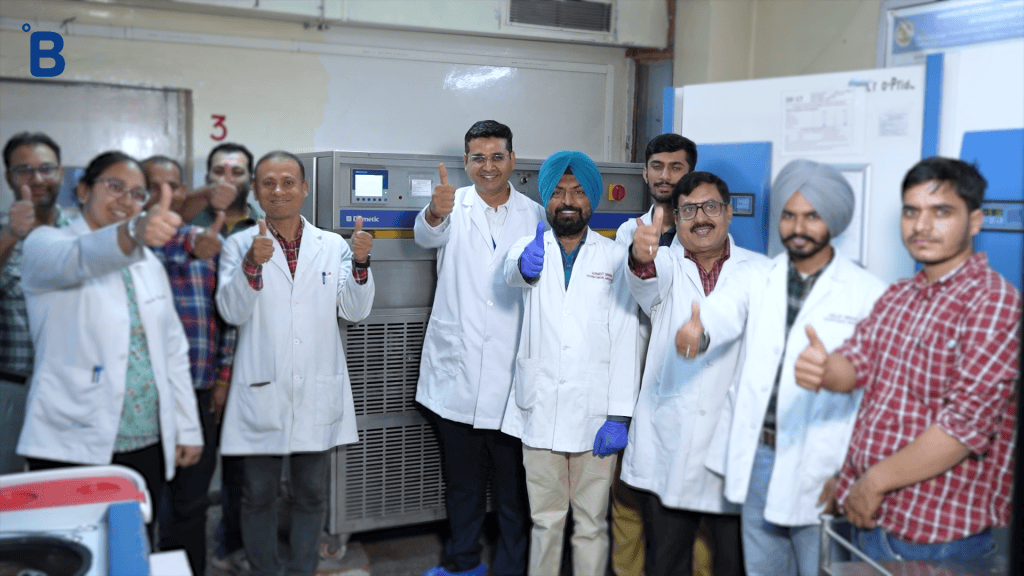

Testimonials

What do experts think about us? Post Graduate Institute of Medical Education & Research, Chandigarh, India

Through these brief conversations, we aim to understand our customers’ perspectives. Today, we are visiting Chandigrah, India, to speak with Dr. Hari Krishan Dhawan, Head of the Component Lab in Blood Bank Department at Postgraduate Institute of Medical Education and Research (PGIMER). It is a public medical university in Chandigarh, India. It is an ‘Institute of National Importance’. It is the leading tertiary care hospital of the northern India region, offering 24 different post graduate courses, 40 super speciality courses and Doctor of Philosophy (PhD) courses in all medical and non medical disciplines along with 24 paramedical under and post graduate courses. Annually, it caters to over 1000000 patients in outpatient department and about one lakh patients in various emergency and inpatient departments. At present there are 160 speciality and super-speciality OPDs and numerous laboratory facilities serving patients nation-wide from all walks of society.

- Could you explain what the activities of the center consists of?

At the blood center within the Postgraduate Institute of Medical Education and Research in Chandigarh we oversee the component preparation division, which is one of the largest hospital-based blood centers in the country. On a daily basis, we collect approximately 200 units of blood, amounting to 60,000 units per year. Our responsibilities include the preparation of various blood components such as plasma and platelets. We meticulously handle the storage, labeling, and transportation of these components to the issue sections. Our focus lies in efficiently managing the logistics of storage, minimizing wastage and breakage, and optimizing the viability of the components to ensure that patients receive maximum benefit from our services.

- Why is there a need of cold storage in your business?

In the laboratory, maintaining blood components at appropriate temperatures is of utmost importance for a blood center. It is imperative to preserve the viability of active components, ensure the stability of coagulation factors in plasma, and maintain the viability of platelets and red cells in their respective products. Thus, the primary focus is on maintaining the cold chain effectively According to regulatory requirements, red cells must be stored at a temperature of 4°C ± 2°C throughout their storage period. Plasma, referred to as fresh frozen plasma, must be stored at or below -30°C within six hours of collection. Platelets must be prepared within six hours of collection and stored at a temperature of 22°C ± 2°C for up to five days. These stringent temperature controls are essential to uphold the quality and integrity of blood components for patient transfusions.

- Which products did you buy from B Medical Systems? For which purpose?

We have been using MBF21 blood plasma contact shock freezer, previously known as Dometic and now under B Medical Systems, to rapidly freeze plasma upon labeling. Subsequently, the plasma is stored at -40 degrees Celsius, in compliance with regulatory requirements.

- What are the features that you liked the most? Could you please talk about the performance of the devices?

The standout features of the MBF21 contact shock freezer, formerly Dometic and now under B Medical Systems, have significantly addressed our plasma storage challenges. This freezer facilitates fast freezing of plasma and the shaping of plasma units post-labeling, streamlining the process for subsequent blood grouping and TTA testing. Moreover, it notably reduces or eliminates breakage of the satellite tubes, enhancing overall yield of factor VIII and fibrinogen, as evidenced by research conducted during an MD thesis.

- How are you using B Medical Systems’ products and how do they benefit your institution?

Over the past decade, this contact shock freezer has proven to be highly reliable with minimal breakdowns, contributing to our operational efficiency in storing plasma. One of its key benefits is its ability to decrease the workload on deep freezers. By using the contact shock freezer for initial freezing and subsequently storing plasma units in regular freezers, we’ve minimized temperature fluctuations and compressor strain. This approach not only optimizes plasma storage conditions but also extends the lifespan of other equipment used for plasma processing and storage. Overall, the use of this equipment has significantly improved our organization’s plasma storage practices and operational efficiency.

- Have you found in B Medical Systems a trustworthy partner?

Yes, B Medical Systems is indeed a trustworthy partner.

- How did you learn about B Medical Systems?

We learned about B Medical Systems at one of the medical conferences.

- How long have you been a B Medical Systems customer?

We have been a customer of B Medical Systems since 2011.

- Are you satisfied with the equipment?

Yes, we are satisfied with the equipment. Overall, our experience has been good. We have encountered very few significant breakdowns during the decade of use.

- Would you recommend B Medical Systems?

I would recommend B Medical Systems, especially to medium and high-volume blood centers. It effectively addresses the challenges of freezing and storing plasma units.