Rotational Moulding / Rotomoulding is a process for producing hollow parts by placing a resin, normally in the powder form, into a mould and then rotating the tool in multiple axes in an oven until the powder melts completely and coats the inside of the mould cavity. This is followed by cooling the mould which solidifies the product and is then taken out for further processing.

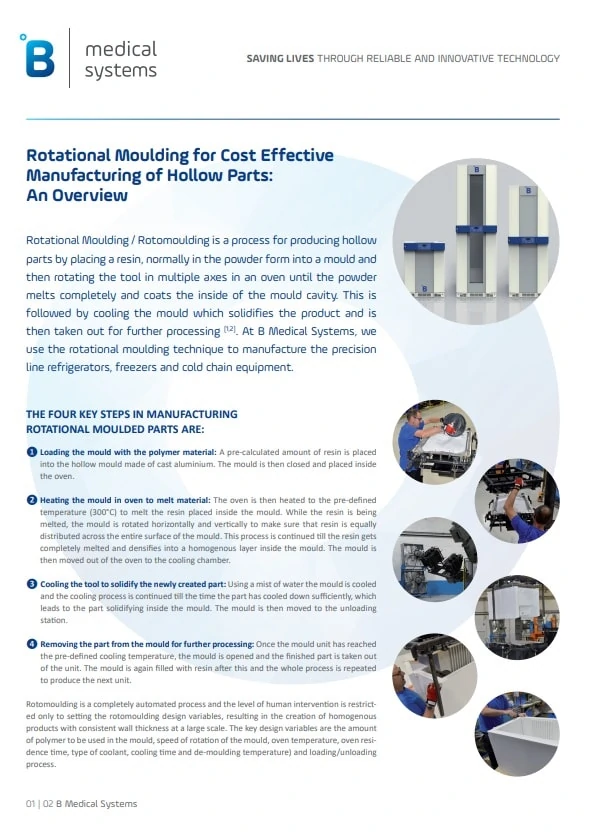

At B Medical Systems, we use the rotational moulding technique to manufacture the precision line refrigerators, freezers and cold chain equipment.

This paper explains the four steps of the process and the raw materials used, as well as the benefits in terms of costs and quality.